About Us

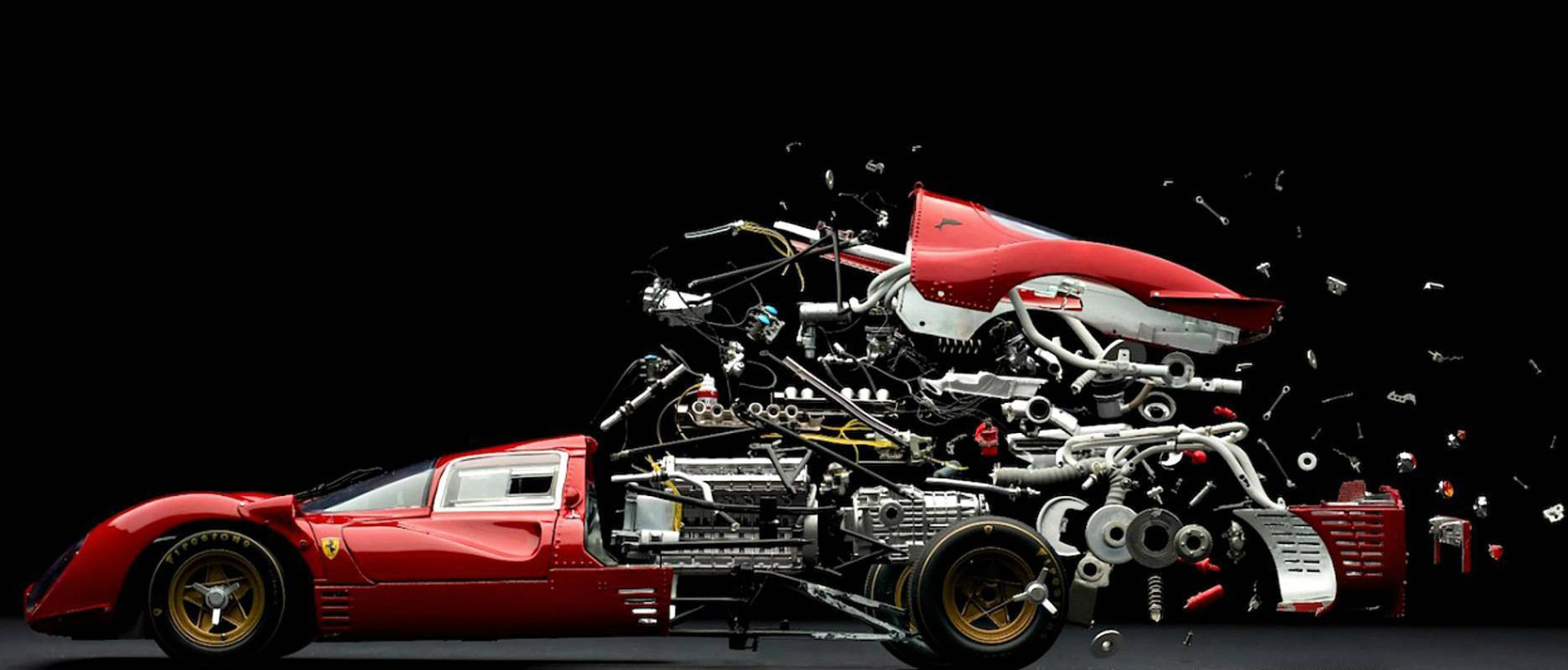

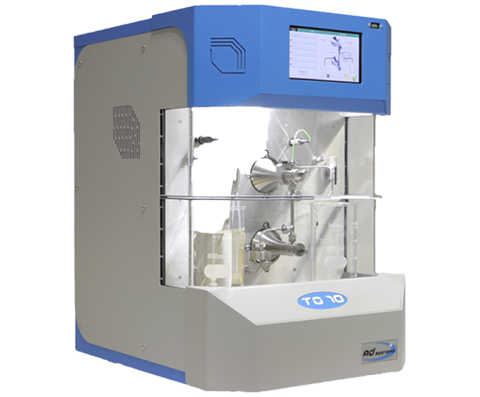

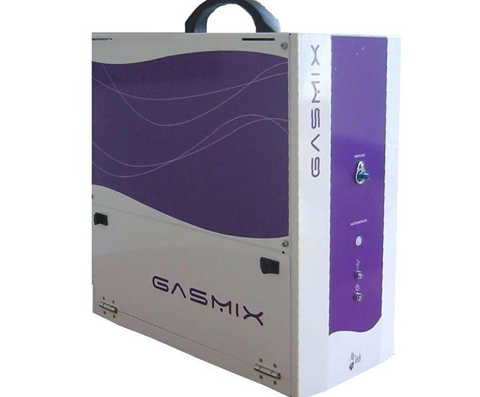

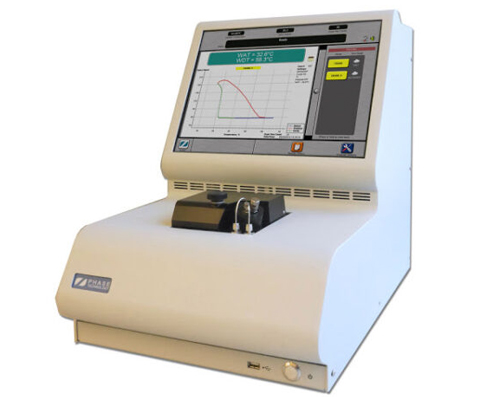

Established in year 1986 , Elico Marketing offers high quality & reliable laboratory instruments for fuels and materials testing in India. We partner with industry’s most trusted brands, backed by nationwide service network offering both field and in-house service.